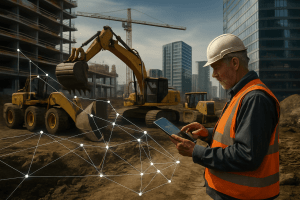

Construction projects rarely fail because of a single, obvious issue. More often, it’s the hidden costs, those quiet, untracked inefficiencies, that gradually eat away at budgets, timelines, and margins. The problem is that many of these costs go unnoticed until it’s too late. Without real-time data, you’re essentially managing blind, relying on incomplete reports or outdated spreadsheets.

Overlooked Expenses in Construction: How Data Turns Losses Into Savings

1. Idle Time That Looks Invisible

Equipment sitting idle may seem harmless, but every unused hour is still burning fuel, labor, and capital. Across a project, idle time can account for 20–30% of machine hours. Without data, this waste gets buried inside “normal operations,” and project leaders only notice when fuel bills spike or deadlines slip.

With visibility: Real-time tracking shows exactly when machines are running, idling, or offline. Managers can intervene immediately, reassigning assets, balancing utilization, and cutting idle time before it drains budgets.

2. Fuel & Energy Drain

Fuel is often one of the top three operating costs in construction. But without granular monitoring, leaks, unauthorized drains, or simple overuse hide in the system.

- A refuel might look normal on paper.

- A generator running overnight might never be logged.

- Inefficient routes or bottlenecks may double consumption.

With data: AI-powered platforms can flag abnormal fuel use instantly, highlight trends, and identify unauthorized drains. Small corrections compound into major savings, often 10%+ reductions in fuel spend.

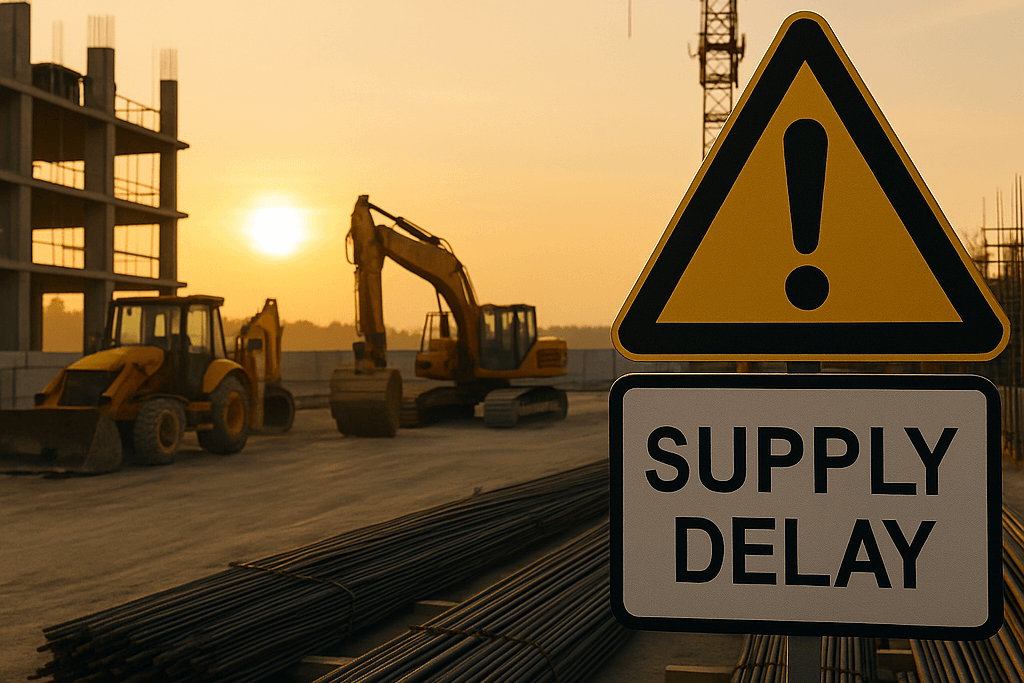

3. Delays Hidden in the Supply Chain

It’s easy to blame late deliveries on external factors. But often, the real cause is congestion, inefficient routes, or underutilized equipment. Without data, these operational slowdowns remain invisible, reported only after projects fall behind schedule.

With visibility: Heatmaps and activity tracking expose bottlenecks in real time. Adding a loading bay, redistributing trucks, or reallocating excavators can lift productivity by 20–30% in just weeks.

4. Maintenance Blind Spots

Traditional logs and spreadsheets only capture breakdowns after they’ve already happened. Unplanned downtime is expensive, not just in repair bills, but in cascading delays across the project.

With data: Predictive maintenance powered by live sensor data catches small issues before they escalate. Instead of waiting for machines to fail, teams can schedule service proactively, reducing downtime and extending asset life.

5. Compliance & Sustainability Gaps

Owners and regulators are increasingly asking for proof of emissions reduction and sustainability reporting. Without data, companies scramble to pull together estimates or incomplete reports, risking penalties, reputational damage, or losing bids.

With visibility: Automated CO₂ tracking provides verifiable reporting across mixed fleets. This turns compliance into a strength, helping companies not only meet requirements but also stand out in competitive tenders.

The Bigger Picture: Data Is Profit Protection

Hidden costs aren’t small, they’re silent profit killers. When multiplied across fleets, sites, and months of operations, the waste can run into millions. Data doesn’t just highlight problems; it gives managers the clarity to act fast, course-correct, and protect margins.

At Tenderd, we see it every day: once companies gain real-time visibility into their operations, they quickly uncover inefficiencies they didn’t even know existed and unlock measurable savings in fuel, time, and emissions.

For example, one of our major construction customers achieved in their first year of tracking with Tenderd:

- 15% boost in productivity

- 27% cut in idling emissions

- 18% downtime decrease

These results weren’t achieved through drastic changes, but by exposing the hidden costs and acting on real-time data. Download the case study to learn more about this project.

Conclusion

Managing construction projects without real-time data is like steering in fog: you’ll eventually get where you’re going, but not without wasted time, resources, and risk. By shining light on the hidden costs, idle time, fuel waste, delays, breakdowns, and compliance gaps, data-driven visibility helps companies turn inefficiency into opportunity.

Ready to see what hidden costs your project is carrying?

Email us at info@tenderd.com or book a demo to discover how TENDERD can future-proof your operations.